Only through a commitment by all of Delta’s employees to comply with requirements, continuously improve and maintaining the most effective Quality Management System can this be achieved!

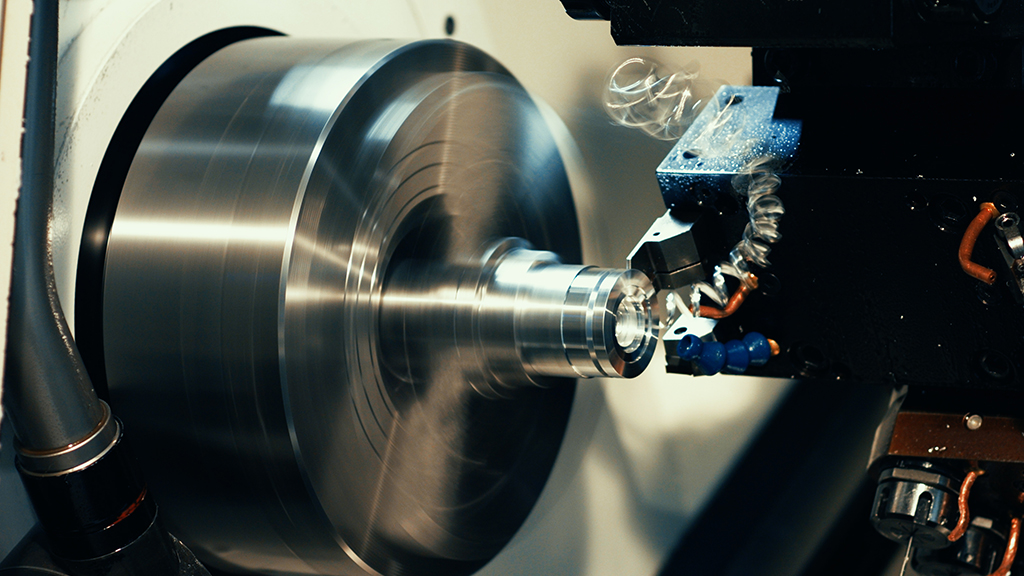

Milling Drilling, Boring

Turning: Contour Turning, Form Turning, Taper Turning, Straight Turning

Threading: External, Internal Tapping, Thread Milling, Internal Forming, Knurling, Counterboring, Countersinking, Pocketing, Profiling, Reaming, Parting/Cutting, Facing

CNC Control Capabilities, Large Swing Lathe, Bar Feed, Milling, CAD Design Services, CAM Programming Services, Reverse Engineering

ISO 9001 Certification, CMM Inspection Capabilities, ANSI, AS, ASME, ASTM, AWS, CSA, DOT, FDA, Mil-Spec, NADCAP, QS, RoHS, SAE, TS

Six Sigma Certification, Yellow Belt, Green Belt, Black Belt, Lights Out Manufacturing, Lean Manufacturing

AutoCAD (DWG, DWZ), BMP, Catia (CATDrawing, CATPart), Delcam (DGK, DMT), DXF, GIF, IGES, Inventor (IDW, IPT), JPG or JPEG, PDES, PDF, SAT, SolidEdge (DFT), SolidWorks (SLDPRT, SLDDRW, SLDDRT), STEP, TIFF, TurboCAD (TCW, TCX), Unigraphics (PRT)