The Supplier must notify DELTA HI-TECH if any of the following requirements cannot be achieved before acceptance of a DELTA HI-TECH purchase order.

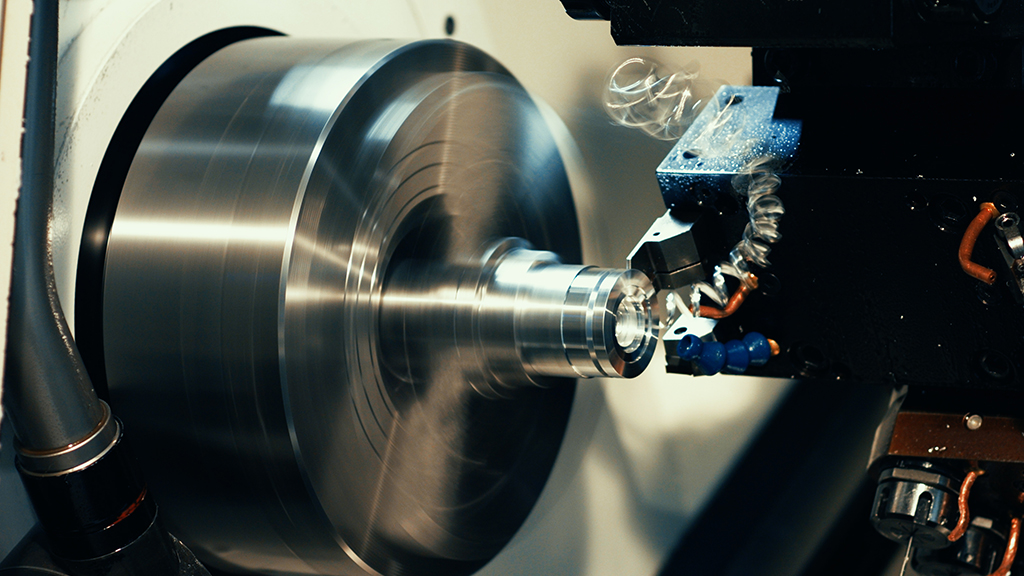

QA 1 Machining and/or manufacturing suppliers must furnish a certificate of conformance with the product being shipped. If the supplier purchases material or performs processing on the products ordered, then the supplier must furnish material and processing certifications. Manufacturing plans, inspection reports and documents related to the products purchased must remain on file with the supplier and be available upon request. The record retention requirements for suppliers states that records must be retained for 10 years minimum unless extended retention times are required by DELTA HI-TECH or its customers, these additional retention times will be noted on DELTA HI-TECH purchase orders when required. Hard-copy (paper, mylar, etc.) records should be shredded or rendered unreadable before disposal after retention period has expired. Electronic records should be permanently deleted from the computer system (all computers, servers, hard-drives, etc.) after retention period has expired.

QA 2 Documented first article inspection reports shall be submitted to Quality prior to the beginning of production. The supplier assumes all financial responsibility for material, rework and/or replacement when production of parts is begun without first article inspection approval from DELTA HI-TECH.

QA 3 AS9102 First Article forms are required.

QA 4 This Purchase Order contains requirements for the approval of product and services, methods, processes, and equipment and/or requirements for the competence or qualifications of the personnel used to fulfill this order. If specific approvals exist for the release of products and services they will be listed on DELTA HI-TECH purchase order. See the DELTA HI-TECH purchase order for the specific approvals that are required.

QA 5 DELTA HI-TECH requires machining and/or manufacturing suppliers to have a quality management system in accordance to AS9003, AS9100, AC7112, AC71122/2 or ISO9001. DELTA HI-TECH may make conditional exceptions based on supplier survey information or applicable customer requirements.

QA 6 DELTA HI-TECH has documented the identification and revision status of the applicable specifications, drawings, process requirements, inspection/verification instructions and other relevant technical data on the supplier’s purchase order. See the purchase order for specific details related to the applicable specifications, drawings, process requirements, inspection/verification instructions and other relevant technical data.

QA 7 DELTA HI-TECH has documented the applicable requirements for design, test, inspection, verification (including production process verification), use of statistical techniques for product acceptance, and related instructions for acceptance by the organization, and as applicable critical items including key characteristics on the supplier’s purchase order. See the purchase order for specific details related to the applicable requirements for design, test, inspection, verification (including production process verification), use of statistical techniques for product acceptance, and related instructions for acceptance by the organization, and as applicable critical items including key characteristics.

QA 8 DELTA HI-TECH has documented the applicable requirements for test specimens for design approval, inspection/verification, investigation and/or auditing on the supplier’s purchase order. See the purchase order for specific details related to the applicable requirements for test specimens (e.g., production method, number, storage conditions) for design approval, inspection/verification, and investigation or auditing.

QA 9 The supplier must notify DELTA HI-TECH of nonconforming product by phone, email or fax when a nonconformance has been identified. The supplier must obtain DELTA HI-TECH’s approval of the supplier’s disposition of nonconforming material.

QA 10 The supplier must notify DELTA HI-TECH of changes in the product and/or process, changes of suppliers, and/or changes of the manufacturing facility location. The supplier must obtain DELTA HI-TECH approval in writing to change any contract requirement. If DELTA HI-TECH agrees to the change, only customer-designated or approved suppliers, including process sources (e.g., special processes) may be used.

QA 11 The supplier must flow down to its supply chain the applicable DELTA HI-TECH requirements including customer requirements.

QA 12 The supplier shall use industry standard, commercially reasonable efforts to prevent and or remove foreign objects that might be considered a potential source of Foreign Object Damage (FOD) from all DELTA HI-TECH products prior to shipment.

QA 13 In addition to DELTA HI-TECH’s right of access, the supplier agrees to right of access for DELTA HI-TECH customers, and regulatory authorities to the applicable areas of all facilities at any level of the supply chain, involved in the order and to all applicable records in the performance of this contract.

QA 14 Suppliers are required to notify quality prior to transferring any work to a new facility. DELTA HI-TECH will determine (prior to the transfer) if the supplier may perform the transfer of work.

QA 15 Any delay in shipment for any reason has to be conveyed to DELTA HI-TECH quality by phone, email or fax as soon as the delay is known by the supplier.

QA 16 Requirements for the supplier to comply with executive order E13224. Supplier shall not engage in any transaction of any type with persons or businesses or organizations who commit, threaten to commit or support terrorism.

QA 17 All information in the contract must be held in confidence by the supplier and no third-party request for information will be authorized unless instructed in writing by a DELTA HI-TECH representative. When ITAR and/or government rated data is noted on the purchase order, the US government restrictions must be followed. If you have any questions concerning ITAR or government rating notify the company buyer. All concerns must be answered prior to you accepting this order.

QA 18 All processing suppliers that use conflict materials (Tin, Tantalum, Tungsten, and Gold) must ensure that these materials come from a conflict-free source per the Dodd Frank act section 1502. An EICC Reporting template must be completed and sent to DELTA HI-TECH before the first shipment of product to DELTA HI-TECH Co.

QA 19 DELTA HI-TECH monitors suppliers’ performance on an ongoing basis DELTA HI-TECH tracks on-time delivery (OTD) and product conformity (PC). DELTA HI-TECH has established a minimum performance threshold of 95% product quality and 90% OTD. If minimum performance is not achieved by the supplier, supplier may be contacted by DELTA HI-TECH Management and corrective action will be requested.

QA 20 Supplier must have a process for training and detection of counterfeit products in order to prevent the use and proliferation of counterfeit products.

QA 21 Supplier must ensure that all its personnel are aware of their contribution to product or service conformity; their contribution to product safety; and the importance of ethical behavior.

PRC-1 Processing suppliers must furnish processing certifications to DELTA HI-TECH purchase order requirements, and shall not process any parts for which they are not certificated or approved. Acceptable quality management system requirements are AC7004, ISO9001, or AS9100; DELTA HI-TECH may make conditional exceptions based on supplier survey information or customer requirements. Suppliers must have the ability to ensure the adequacy of the special-process provided and provide DELTA HI-TECH the required documentation per purchase order requirements.

For Processing suppliers QA 6, QA 7 – QA 21 are applicable.

MAT-1 Material suppliers must furnish material certifications to DELTA HI-TECH purchase order requirements, and shall not supply material for which they are not certificated or approved. When noted on our purchase orders, raw material supplied must be USA domestic material. Acceptable quality management system requirements are ISO9001, AS9100 or AS9120; DELTA HI-TECH may make conditional exceptions based on supplier survey information or applicable customer requirements. The Supplier must have the ability to ensure the adequacy of the product provided and provide DELTA HI-TECH the required documentation per purchase order requirements.

For Material suppliers QA 6, QA 8, QA 9, QA 10, QA 11, QA 12, QA 13, QA 15 – QA 21 are applicable.

MFG-1 The Supplier must have the ability to ensure the adequacy of the product provided to DELTA HI-TECH and provide the required documentation per purchase order requirements. For Machining and Manufacturing suppliers QA 1, QA2, QA3 and QA 5 thru QA 21 are applicable.

CAT-1 Calibration and Testing suppliers must furnish calibration/test reports to DELTA HI-TECH purchase order requirements, and be traceable to the specific equipment or item for which they are calibrating or testing, traceability to NIST and/or other national or international standards must be supplied. ISO9001, ISO 17025, Nadcap testing, ANSI Z540, and/or Navlap accreditation will be the quality management system requirements; DELTA HI-TECH may make conditional exceptions based on supplier survey information or applicable customer requirements.

CALIBRATION MUST ADHERE TO ISO 17025 REQUIREMENTS.

For Calibration and Testing suppliers QA 6, QA 8 – QA 21 are applicable.

This document describes the minimum quality requirements acceptable to conduct business with Delta.

2.1 This document is applicable to all Delta Products Eternal Providers of products and/or services and is independent of any additional requirements contained within the purchase order.

2.2 The flow down of this document is in accordance with Delta’s Quality System Manual, and the requirements of ISO9001 and AS 9100.

3.1 Right of Access

3.1.1 The external provider shall allow the right of access by Delta and/or their customers and regulatory authorities to all facilities during the manufacturing and/or processing of the order, and to all applicable documents.

3.2 Inspection

3.2.1 The external provider shall maintain a Quality / Inspection system in compliance with ISO 9001 / AS9100 requirements to ensure the prevention of shipping nonconforming product.

3.3 First Article Inspection

3.3.1 The external provider shall provide Delta with a completed FAI of work performed, when specified per Purchase Order requirement on first production run of a new part or following any change that invalidates the previous FAI results. First Article Reports shall be in accordance with AS 9102 format when required by Purchase Order.

3.4 Calibration

3.4.1 The external provider shall control the calibration of all measurement equipment used accept or reject products or services. Inspection, measuring, and test equipment shall be controlled, calibrated, and maintained in accordance with ISO 17025 and or ANSI/NCSL Z540-1.

Calibration shall be traceable to National or International Standards. It is the responsibility of the supplier to return any customer supplied equipment to Delta prior to the calibration due date.

3.5 Customer Approved Process Sources

3.5.1 The external provider shall ensure the use of any designated customer-approved special process source as indicated on purchase order or other specific instructions.

3.6 Flow Down Requirements

3.6.1 The external provider shall ensure the flow down of all applicable purchase order requirements to any sub-tier supplier, including any specific or key characteristics where required.

3.7 Control of Documents

3.7.1 The external provider shall control all documents supplied by Delta pertaining to the order. It is the responsibility of the external provider to destroy any documents supplied by Delta that are obsolete or superseded. The supplier may choose to utilize their internal document control process.

3.8 Control of Records

3.8.1 The external provider shall retain all process, inspection, certifications and test documents/records pertaining to the order for a minimum of ten (10) years. When requested, the supplier shall provide Delta with copies of records pertaining to specific orders within 2 working days of request.

3.9 Certifications and Inspection/Test Data

3.9.1 The external provider shall provide certification of conformance, and where applicable, inspection and/or test data with each shipment. Certifications to specifications shall reflect the latest revision level unless otherwise noted on purchase order.

3.10 Nonconformance Notification

3.10.1 The external provider shall notify Delta of any non-conformances identified prior to and /or after product delivery. Supplier shall submit a deviation/waiver request along with nonconforming product to Delta for evaluation and subsequent disposition.

3.11 Change Notification

3.11.1 The external provider shall notify Delta prior to any changes to the product, processes, suppliers, facilities, tooling and or gages relevant to the order.

3.12 FOD (Foreign Object Debris)

3.12.1 Foreign Object Debris is not allowed. All parts must be verified 100% for this condition. Any FOD identified must be removed prior to shipment to Delta.

3.13 Packaging

3.13.1 The supplier shall package products appropriately to avoid the possibility of damage of product / services ordered during shipment.

3.14 ITAR’s Compliance and DPAS Flow-down

3.14.1 When the Delta Purchase Order identifies ITAR’s Compliance and that the information contained may be subject to International Traffic Arms Regulations (ITAR) or Export Administration Regulations (EAR) Controls and may not be disclosed to any foreign person(s) or firm, including persons employed by or associated with your firm, without first complying with all requirements of the ITAR, 22 CFR 120-130 and the EAR, 15 CFR 730-774, ITAR’s Regulation’s / compliance / controls shall be required.

By this notification, you as a Delta external provider have been so advised of its compliance obligations under the ITAR.

3.14.2 DPAS Rating – Government Order certified for National Defense.

When a ‘DPAS RATING’ is identified on Delta’s vendor Purchase Order, it is Supplier / Processor’s responsibility to comply and follow all provisions of the Defense Priorities and Allocation System Regulation – (15 CFR 350).

3.14.3 Domestic Specialty Metals – Any specialty metals incorporated in articles produced and delivered under this contract shall be melted in the United States or qualified country in accordance with DFARs 252.225-7014, Preference for Domestic Specialty Metals.