We provide superior results in these markets:

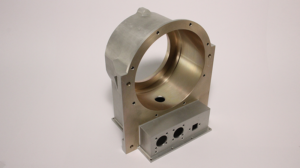

These are examples of the types of products we manufacture:

Implants and instruments for

shoulders and small joints

Implants and instrumentation

for hips and knees

Plates and bone screws

Forceps, accessories and suture anchors

Fixation plates, pedicle screws and spinal cages

Sterilization Trays

Delta provides products and services that consistently exceed customers’ exacting requirements. This is achieved by full conformance to all specifications, constant process improvements and robust training programs to enhance employee skills. In addition, real-time statistical process control (SPC) systems monitor key variables throughout manufacturing to maintain consistent quality and ensure processes are statistically stable.

Our validation, qualification and process controls ensure compliance to all applicable regulations and customer requirements. Our strategy includes quality and performance goals in all functional areas and it is our objective to raise the bar for compliance, giving our customers the reliability that their markets demand. At Delta Medical quality is a culture of continuous improvement that starts with the President and extends throughout every branch of the organization.