8′ AMADA M-2560 Shear with Pneumatic Sheet Support and Automatic Back Guage, AMADA Notcher CS-220, Cuts material up to 1/8″ thick, 9.025″ long.

2 TRUMPF TC2000 20 Tons, 11 Station, 50″ x50″ Travel, Windows 2000 Based Control

AMADA Pega 305072, 58-Station Turrett, 30 Tons, 50″ x 72″ Travel, Amada 04P-C Control with Hydraulic Clutch

BYSTRONIC Byspeed 4020 Max size 5’x10′, 4.4kW, 3G acceleration

AMADA FOL3015 4kW Fiber Laser – 5’X10’, 14,000ipm rapids, 5G acceleration

2 TRUMPF Truma Bend V130 146 Tons, 120″ Max Bend Length, Intelligent 6-axis back gauge

AMADA HDS1303 NT 124” Bend length, 130 Tons

AMADA HDS8025 NT 100” Bend length, 80 Tons

AMADA RG50: 50 Tons, 72″ Max Bend Length, Automatic Back Gauge

AMADA RG35: 35 Tons, 49.3″ Max Bend Length, NC9-EX Fully Automatic Control

PACIFIC K200-12 200 Tons, 12′ Max Bend Length, Automatic Back Gauge

HAAS VF2-YT Milling Machine with Renishaw Probe

FADAL 4020 Milling Machine

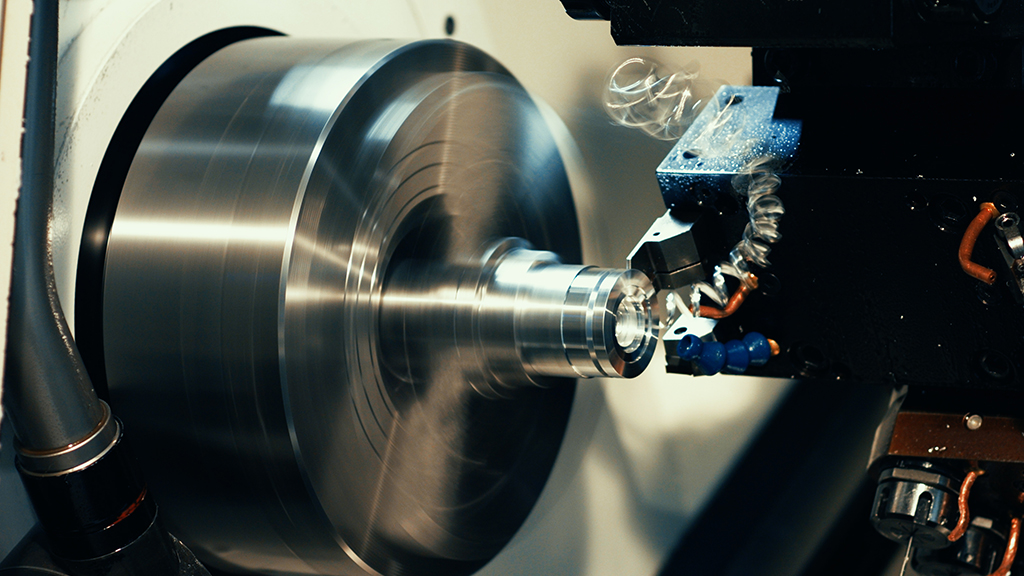

HAAS ST10 Turning Center

3 Conventional Mills with Digital Readout

Conventional Lathe, Swing = 14″ Dia., 25″ Between Centers

AMADA TEG-160ES Die surface Grinder

DORINGER D350 Coldsaw, 8″ Width

COSEN C200W Horizontal Band Saw, 12″ Width

FLEXARM Portable Tapping Machine

1 Miller Dynasty TIG 350 Welding System

1 Miller Millermatic MIG 251 Welding System

2 Miller Syncrowave TIG 250 Welding System

1 Lincoln Square Wave TIG 275 Welding System

2 Lincoln Power MIG 255C Welding System

2 Lincoln Power MIG 255 Welding System

1 Lincoln Square Wave TIG 255 Welding System

1 Lincoln Writematic MIG 255 Welding System

1 SCIAKY Three-Phase Spotwelder (Aluminum Spotwelder)

1 LORS Spotwelder

1 JANDA Spotwelder

1 AEM Grainer, 2′ Wide

1 AEM Grainer, 3′ Wide

1 CYCLONE Sandblasting System

2 Tumble Deburring Machines

Various Handtools and Bench Grinders

FENNER Automatic Roller, 0.187 thick over 7.5′ Capacity

DOM FHA Model DFX-610 Roller, 0.048 thick over 24″ Capacity

JET Model SR-118 Roller, 0.037 thick over 12″ Capacity

2 HAGAR Press machines, with 2,950 psi Maximum Pressure – 1 Machine equipped with Fully automatic Modular Autofeed System.